Sellier & Bellot, founded in 1825, is one of the world's oldest companies in the ammunition and defense industry and ranks among the most important industrial companies in the Czech Republic.

Over the years, we have become a traditional manufacturer of small caliber ammunition, supplying premium ammunition to Czech and foreign armed forces as well as to customers in the commercial market.

Sellier & Bellot's product portfolio includes a wide range of hunting and sporting ammunition, pistol, revolver, rifle, shotgun and rimfire ammunition. Modern technologies used at all stages of production guarantee products of the highest quality. We place emphasis on innovation. Some of our most important recent innovations include lead-free bullets for hunting and police applications, patented products such as the Nontox match compound and the launch of infrared tracer bullets.

The majority of our production is exported, with the United States and Europe being our largest markets. We are a major supplier of ammunition to military and police forces around the world, including armed forces of various EU countries.

Sellier & Bellot, founded in 1825, is one of the world's oldest companies in the ammunition and defense industry and ranks among the most important industrial companies in the Czech Republic.

The flexibility of our production allows us to meet special requirements of our customers for the ammunition production. We follow C.I.P. standards for commercial ammunition, and primarily NATO standards for military production. Quality management is ensured by ISO 9001, 14001 and military standards, which are confirmed by a number of certifications and regular audits.

In 2024, Sellier & Bellot became part of Colt CZ Group SE, one of the world’s leading manufacturers of firearms, tactical accessories and ammunition for military and law enforcement, personal defense, hunting, sport shooting and other commercial use. Its products are marketed and sold mainly under the Colt, CZ (Česká zbrojovka), Colt Canada, Sellier & Bellot, Dan Wesson, swissAA, Spuhr a 4M Systems brands. Colt CZ Group is headquartered in the Czech Republic and employs more than 3,600 people in its production facilities in the Czech Republic, the United States, Canada, Sweden, Switzerland, and Hungary. Colt CZ has been listed on the Prague Stock Exchange since 2020 and the majority shareholder is Česká zbrojovka Partners SE holding.

History Overview

Embark on a journey of ages of the Sellier & Bellot company.

- 1786

- The French Chemist Bertholet first prepared potassium chlorate. He discovered that when it was mixed with solid combustibles (e.g. powdered wood charcoal, powdered sulphur) it became responsive to external stimuli (friction, impact,

puncturing), whereby an explosion was induced.

- 1790

- In Paris Pierre Daniel Louis, the seventeenth of a total of nineteen children was born to the Sellier family. Two of his brothers were guillotined during the French Revolution"

- 1797

- A son who was named Jean Maria Nicolas was born to the Bellot family, who were living in Fontainebleau in France. In this town the Bellots ran a horse-exchange station for stagecoaches and a hotel."

- 1799

- The Englishman Edward Charles Howard rediscovered mercury fulminate. In previous times Alchemists had been familiar with this substance but it had been forgotten. It is in itself primary explosive and it is possible to effect its detonation

by means of a slight external stimulus.

- 1809

- Louis Sellier emigrated from France in order to avoid having to serve in Napoleon's army. Using the name Dell, he resided in Hamburg and in St. Petersburg. During this sojourn he acquired extensive insight and experience of international

trade.

- 1813

- Sellier, together with his relative, Barthelemy Sellier, purchased the Rosenkranz Company in Leipzig and transformed it into Sellier & Comp. The company was engaged in the sale of luxury goods (crystal glass, bronze products) and

additionally of hunting weapons and accessories.

- 1815

- Sellier was paying secret visits to Paris, where he met Annette Huré, the daughter of Andrea Huré, the Governor of the French area of St. Martin island in the Lesser Antilles. Sellier asked her father for Annette's hand in marriage, but he

was rejected and Annette was sequestered in a monastery from which Sellier kidnapped her and, in October 1815, their son was born. They did not get married, however, until February 1816. Sellier and his wife then moved to Leipzig, where he

devoted himself to the full-time management of his company.

- 1819

- Nicolas Bellot studied chemistry at the Polytechnic School in Paris, where he encountered both potassium chlorate and mercury fulminate. Under the supervision of Julien Leroie he continued with Bertholet's work from the 1780's on the

introduction of primers for military ammunition made from a mixture of potassium chlorate with black powder."

- 1820

- From around 1820 the setting-up of workshops for the production of percussion caps started to increase in France, England, Prussia, and the U.S. These workshops were largely initiated by gun makers, who were converting guns with flintlocks

for use with percussion caps. They did not have the requisite experience for the production of primer compositions and produced primers in a rudimentary manner and they were consequently expensive.

- 1822

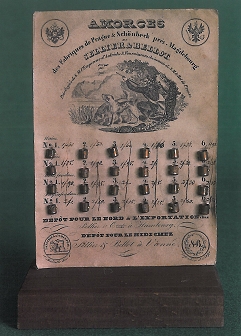

- Nicolas Bellot together with his associate, Daguien, requested permission to build a workshop in Paris for the production of percussion primers. A permit was granted to them on 20th August 1823. In addition, Bellot worked as a silent

partner with the Paris company Tardy & Blancher. The primers from Bellot's workshop had excellent properties and rapidly gained commercial success. Sellier & Comp. in Leipzig also started to become engaged in their sale. Sellier was an astute

businessman. He foresaw the emergence of a new cap system for small arms and decided to initiate his own production of percussion caps. In France, England, and Prussia there already existed workshops for their production. Sellier decided to

establish the manufacture of percussion caps in the Austrian Empire, in Prague, the capital of the Bohemian Crown.

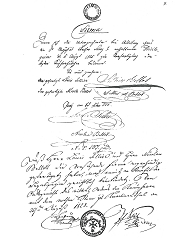

- 1825

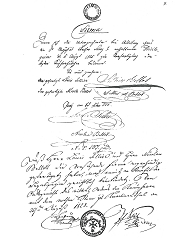

- At the beginning of the year 1825 Sellier & Comp. requested from the Austrian authorities a privilege for making percussion caps. Sellier, however, did not wait for the issuance of the privilege and initiated the first attempt at their

production near Prague, in the former Zbraslav monastery, in a chemical factory belonging to A. Richter. Without professional guidance, the manufacturing operation failed however. The Austrian authorities were meanwhile discussing Sellier's

request for a privilege. The Austrian Emperor Francis I issued this, however, with the proviso that the production would be supervised by a person familiar with this "art". Sellier, influenced by his own unsuccessful attempts to

introduce the production of percussion caps and as a consequence of the requirement defined in the privilege granted by the Emperor, sought Bellot's cooperation. Bellot agreed that he would start production in Prague and train local workers.

This agreement was reached in August 1825 and this year is considered as that of the founding of the S & B Company. Bellot came to Prague in autumn 1825 and undertook the establishment of a workshop for the manufacture of percussion caps in a

former vineyard estate at "Parukářka", outside the walls of Prague that Sellier had already purchased. On 22nd December 1825 Sellier and Bellot asked the Austrian authorities to either allow them the right to exercise the privileges

granted by the Emperor Francis I, or to grant them a concessionary licence for the manufacture of percussion caps.

- 1826

- The authorities informed the applicants that they could not issue a permit because, in any case, under Austrian Law, foreigners were not permitted to acquire land in Austria for establishing a production company. In late March Sellier and

Bellot requested the granting of an additional privilege for the percussion cap. In the text of the application it is stated that the primer composition is held very firmly in caps, and that these primers do not cause the corrosion of locks

or of gun barrels. It was evident that the primer composition was pressed into the cap and that it contained mercury fulminate in the place of chlorate. The Viennese experts somehow missed these details that were the subject of Bellot's

invention and granted this privilege to the applicants without any problem. The business partners asked the authorities in Prague concerning granting rights to the exercising of this second privilege. During that process it became clear that

the primer composition in accordance with this new privilege contained mercury fulminate. Prague authorities become nervous about this new, completely unknown explosive, and forwarded the application by the business partners to Vienna with a

negative statement, where the industrial production of mercury fulminate in Prague was rejected."

- 1827

- Bellot was a sociable person and was not shy amongst Prague Society. He met the Czech girl, Alžběta Vacková, with whom he became engaged and they were married on 12th July 1827. This Prague marriage obviated Bellot's intention to return to

Paris and he decided to remain permanently in Prague. Marriage with an Austrian citizen enabled Bellot to obtain Austrian citizenship. Sellier was granted a dispensation of the need for Austrian citizenship, which then facilitated their

business activities in Prague."

- 1828

- Bellot's obtaining of Austrian citizenship, his settling in Prague and the granting of a dispensation of the need for Austrian citizenship to Sellier made the bargaining power in the negotiations with Austrian authorities more favourable to

the interests of the business partners. Nevertheless, the negotiations were not so straightforward, because Prague was probably really nervous about permitting the manufacture of mercury fulminate. The result of the lengthy negotiations that

Bellot conducted in Prague (while Sellier was occupied with the management of his business in Leipzig) was the issuance of an Imperial Decree by the Court Office in Vienna, in accordance with which the production of primary explosives in

Austria should be controlled. Based on this decree, the Prague Gubernium issued the Regulation on the Manufacture and Sale of "Firecrackers". The Regulation contained rather up-to-date provisions related to every aspect of the

production and handling of explosives, including, however, a provision extremely unfavourable for the S & B Company, concerning the maximum amount of mercury fulminate to be produced at one time. It was now permitted to produce at one time up

to 12 lots (about 200 g) of mercury fulminate and more was not allowed to be produced until this amount had been used in the composition and pressed into caps. Adhering to this regulation would have actually required the liquidation of the

company. Therefore Bellot was obliged to fill a substantial part of the caps with an explosive mixture based on potassium chlorate.

- 1829

- The Austrian regulation concerning the maximum quantity of mercury fulminate that could be manufactured gave rise to the establishment of another Sellier & Bellot plant in Prussian Schönebeck. There the production of mercury fulminate was

not restricted. In 1829 an exhibition of Czech industrial products took place in Prague. 257 exhibitors from various industries participated in the exhibition and a total of 5 Gold Medals were awarded to exhibitors, one of which was received

by the Sellier & Bellot Company. The Gold Medal was awarded to the producers for their capability for making percussion primers with a total purchase price of 320 kreuzers from one pound of raw materials with a cost of 31 kreuzers. As a

result, during the factory processing by the Sellier & Bellot Company, the native materials contained in one pound of caps obtained a more than 10 times greater value."

- 1830

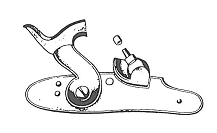

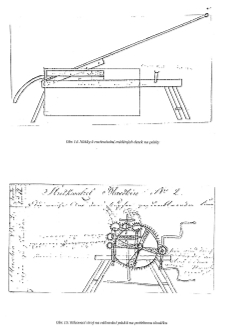

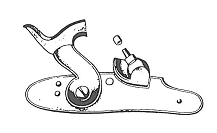

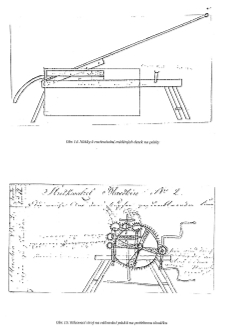

- On 29th March the business partners requested the granting of another privilege. There is a technological process dating from that time for the production of percussion caps, from which it is clear that Bellot had invented a manner in which

to increase their manufacturing productivity and were requesting the granting of a privilege for this technological device. While previously the composition was filled and pressed, one step at a time, into individual caps, Bellot introduced

the use of preparations permitting the simultaneous filling of 100 caps with primer composition and also enabling the pressing of all the 100 caps at the same time. Already while he was in Paris Bellot had been contemplating the production of

primer caps in one operation. Now in Prague he implemented this idea and introduced the utilisation of machines that worked in an "une seule passe" mode, in English “a single pass”. This press, equipped with the necessary tools, in

one movement cut out the roundel, formed the cap, and simultaneously cut it to a precise length. At that time 1000 French copper primers were sold in Vienna for 8 guilders. The same number of Bellot’s caps were sold in the entire Austrian

Empire for 50 kreuzers. By his improvements to the manufacturing technology, Bellot was able to increase the productivity of their manufacture and therefore also offer extremely low prices, which significantly contributed to the success of

guns with a percussion lock over flint-lock guns and enabled the implementation of uniform bullets."

- 1831

- The land, the buildings and the equipment on which caps were made were all owned by Sellier. Bellot contributed to the results of the company with 50% of the profit. On the 1st October 1831, however, Bellot purchased one half of the company

from Sellier, thereby becoming its co-owner.

- 1832

- On 16th February 1832 Bellot was inspecting the manufacture of primer compositions when carelessness on the part of one worker caused an explosion. As Bellot was thrown to the ground fragments of his shattered spectacles penetrated into his

eyes. This accident left him almost blind. Despite this he remained a member of the company's management and contributed to the introduction of new products and the modernisation of their production.

- 1835

- During that year daily production at Parukářka in Prague amounted to 300,000 units of primers. The Gevelot & Co. Company in Paris produced daily 400,000 units of caps, the Tardier & Blancher Company (which was also founded by Bellot)

produced 250,000 units a day, Dreyse & Collenbusch in Sömmerda 150,000 and Sellier & Bellot in Schönebeck 200,000 units of caps. The Sellier & Bellot Company thereby produced in both factories five hundred thousand primers daily, i.e. 150

million annually. It was therefore the largest manufacturer of caps in Europe, and possibly worldwide. At that time the Company employed between 110 and 120 workers.

- 1837

- Bellot sent a new application for the abolition of restrictions on the quantity of mercury fulminate that could be produced. With this request he included additional detailed drawings of the technological process and a description of all

the security measures undertaken. The application was rejected, however.

- 1841

- Prussian riflemen troops were armed with percussion rifles and the Sellier & Bellot Company in Schönebeck received an order for the corresponding primers. Bellot took advantage of this to submit a new application and, on the 27th December

1841, the Court Office permitted the unlimited production of mercury fulminate.

- 1844

- The first steam engine was launched and mechanised production was initiated.

- 1851

- The Company participated in a major exhibition in London, which was effectively the first World's Fair. At this exhibition, for safety reasons, it was strictly forbidden to exhibit flammable objects. This, of course, also included primers.

Bellot therefore created a special varnish, whereby the composition was enclosed in primers and the primers were exhibited submerged in water. After 72 hours they were removed and all of them demonstrated reliable operability.

- 1853

- The production of Flobert and Lefaucheux bullets commenced at the Prague enterprise. For the first time copper rings also constituted an item of the production programme. They were used for reinforcement of the closures of corsets and of

various uniforms and Bellot utilised their production to occupy the spare capacity of the cutting machines.

- 1855

- The S & B factories in Prague and in Schönebeck achieved an annual production capacity of 600 million primers of various designs.

- 1860

- Bellot’s wife died of tuberculosis. She bequeathed her entire personal property worth 13,914 guilders to their children (three sons and three daughters).

- 1865

- 180 million primers and bullets were produced with a value of 80,000 guilders. Primers were sold in the Austrian monarchy, in the German states, in the Balkans and the Middle East, in Russia and in North and South America. In the United

States they achieved such popularity that the percussion caps were generically referred to as SB's. Sellier renounced his share in the ownership of both factories (he passed it on to his children) and retired.

- 1867

- Though Bellot has retired, he retains his share, however, until the clarification of the successor ownership of both plants.

- 1869

- A consortium appears for the establishment of a Joint Stock Company. The members of this consortium are Bellot’s son Alfred, an Imperial Army officer, Bellot’s son-in-law, lawyer Karel Bamberger and 13 other prominent Prague businessmen and

lawyers and one legal entity - the Halla Company. A representative of the Halla Company - Martin Halla negotiated all the purchase contracts for the new corporation.

- 1871

- The S & B factory commenced the production of detonators for the newly built Nobel Dynamit plant in Zámky, close to Prague. No appropriate name yet existed for this new product in any of the languages used in the S & B Company (i.e. Czech,

French and German) and detonators were referred to as "dynamite primers". The director of the Prague factory received a patent for an improved detonator provided with a reinforcing cap.

- 1872

- The Consortium issued a "Punktace" (basically a contract on a future contract) concluded between Dr. Kayser (representing the Sellier heirs), Bellot (as the sellers) and Martin Halla, as the representative of the buyers. The

purchase price for the factories in Prague and in Schönebeck was set at 800,000 guilders, which was to be repaid in four time-specific instalments.

- 1873

- On 10th September 1873 the General Assembly met for the establishment of the Joint Stock Company. It was attended by 25 shareholders, representing the holders of 8,000 shares of 100 guilders each. The Articles of Incorporation were

approved, together with its new name - "Joint Stock Company for the production of primers, ammunition and rings, formerly Sellier & Bellot", a Board of Directors and an Executive Committee were elected.

- 1880

- 100,000 kg of copper, 200,000 kg of brass, 50,000 kg of paper, 5,000 kg of mercury, 60,000 kg of nitric acid and 70,000 litres of ethanol were processed, from which 400 million primers, 20 million detonators, 15 million shells for shotgun

cartridges, 10 million cartridges for revolver and military ammunition and 100 million rings were produced.

- 1883

- A factory was purchased for the production of percussion caps in Riga in Latvia, which at that time was a part of Russia.

- 1892

- Reconstruction and modernisation of the factory. Two steam engines were installed, a traction engine and a wind engine. The implementation of modern safety precautions was initiated. Bulwarks were installed around buildings in which there

existed an explosion hazard, they were heated with hot water and there were first attempts at sewage disposal.

- 1887

- Co-operation with other Austrian manufacturers of caps and bullets, i.e. the Mandl and Hirtenberg Companies. A joint Sales Office was established in Vienna. These firms both cooperated and were competitors.

- 1890

- Production of artillery and sapper detonators. Artillery detonators were supplied to the Skoda Company's munitions plant in Bolevec.

- 1898

- The first joint price list from the "Central Sales Office in Vienna" was issued, including the products of both Sellier & Bellot and Keller & Comp.

- 1910

- The first Sellier & Bellot catalogue in colour was issued.

- 1911

- Construction of additional facilities for expanding the production of ammunition was commenced.

- 1915

- The Austrian Steyr munitions factory, originally considering the construction of its own munitions plant, decided instead to purchase the Sellier & Bellot Company and to expand there the manufacture of ammunition for the needs of the

warring Austro-Hungarian Empire. The sale was effected at the end of 1915 for CZK 1,050 per share.

- 1916

- The Steyr munitions factory built a new hall and gradually equipped it with machines for the production of 8 mm Mannlicher cartridges. In the spring of 1917, the production of this ammunition commenced there.

- 1918

- Creation of an independent Czechoslovakia immediately following its establishment the ownership of the company remains unchanged.

- 1921

- The plant in Schönebeck is removed from the ownership of Sellier & Bellot and comes under the direct ownership of the Steyr munitions company.

- 1922

- Based on a newly approved Czechoslovak law, companies that seek to receive contracts from the Ministry of Defence must be under Czechoslovak ownership. The Czechoslovak Industrial Bank acquired most of the shares of Sellier & Bellot. The

subjects of this purchase were the plant in Prague at Parukářka and the plant in Riga in Latvia. The status of this latter plant was very specific. With the independence of Latvia the Russian market was lost. Meanwhile, in Russia, the

Communist Coup had taken place. The plant thereby remained out of service and other uses were sought for it. In Prague, at Parukářka, production for the Czechoslovakian Army began. Initially of 8 mm Mannlicher cartridges.

- 1923

- The Company cooperates in the development of a new Czechoslovak military cartridges derived from the German 7.92 mm Mauser ammunition for the rifle model 23. Also introduced into production is a new pistol cartridge, the M. 22 derived from

the 9 mm Browning Short (380 ACP).

- 1924

- The production of lead azide and azide-tetryl detonators was introduced. The Company employee Dr. Blechta patents the detonator composition Astryl composed of 97% mercury fulminate and of 3% chemically stable silver azide. This new

composition enables a substantial reduction in the production costs of safe copper mining detonators. The patent was applied in many countries and negotiations were conducted in France concerning its introduction into production. The first

large-scale post-war export of military infantry cartridges took place - 40 million cartridges of 7.92 mm Mauser were exported in Turkey.

- 1927

- After long negotiations with the Latvian military administration, the production of 303 British infantry cartridges for the Latvian army was agreed upon. During a six year period four million units per annum were supposed to be delivered.

The management of the Joint Stock Company had also calculated with the fact that Lithuania and Estonia would also participate with Latvia. Production commenced in 1930 and progressed favourably during the next two years. Contracts with

Lithuania and Estonia were actually concluded together with those from Latvia. Beginning in 1933, however, the orders began to decrease, and finally production was terminated. Long negotiations took place concerning the sale of this plant and

eventually it was agreed that the plant would be sold to the Latvian machinery enterprise Wairogs for L53,500 sterling. The plant was handed over to the buyer, which, however, never paid for it.

- 1930

- The Ministry of Defence informed the Company concerning how much ammunition it would require in the event of an outbreak of war. The main requirements included a daily supply of 1.5 million cartridges of M. 23 and 3.0 million primers. At

its current premises at Parukářka the Company could not give a firm guarantee to provide this amount and therefore it was necessary to expand the production area and to add new machinery. There was not enough room for that at Parukářka,

however. Consideration therefore commenced of the construction of a new plant in a strategic location.

- 1932

- The machinery with which the Company had been equipped was mostly of German manufacture. The overhaul of machines producing ammunition was almost impossible in Germany after the war as also was the purchase of new machinery. In 1932 the

Prague company Košař a spol. was therefore purchased which began to repair and manufacture ammunition machines for S & B. 56 machines were ordered immediately. It was also decided to initiate the construction of a new factory in Vlašim, where

there was both a sufficient workforce and rail connections. The hunting park, with an area of 112 ha, that had been destroyed by a storm in 1929, was bought from Karel Auersperg, an important local estate owner, for CZK 449,728.

- 1934

- The construction of an entirely new factory was commenced. A number of companies from Prague and its vicinity participated in the construction. A colony of family houses and apartment buildings was built for company officials and for senior

employees.

- 1936

- There was a gradual start-up of production at the new enterprise.

- 1937

- The Company obtained a contract from China for 200 million cartridges of 7.92 mm Mauser. The contract had not been completed, however, prior to the outbreak of war. The export of military ammunition during the 1930’s increased, in terms of

financial volume, as follows:

- 1934 – CZK 7.0 million

- 1935 – CZK 12.5 million

- 1936 – CZK 18.2 million

- 1937 – CZK 50.5 million

- 1938 – CZK 53.5 million

- 1938

- 1939

- Due to the occupation of Czechoslovakia by Germany, the enterprise had lost its principal customer - the Ministry of Defence. The Company started to address this situation by seeking for new production programmes. One of these was the

production of high quality zip-fasteners. In autumn the German Armaments Administration ordered from the Company the production of 20 mm calibre anti-aircraft and aircraft ammunition and directed the technical preparations to ensure the

production of infantry ammunition compatible with German technology, i.e. cartridges made from steel, with a phosphated and varnished finish.

- 1940

- The production of lead trinitroresorcinate and of Tetrazene was commenced. The German army submitted orders for the manufacture of 7.92 mm and 9 mm Parabellum cartridges.

- 1943

- Production of 7.92 mm short cartridges (7,92 x 33 Short) was commenced. At the end of the year the German side increased its demand for supplies of this ammunition to 22.5 million cartridges per month. The plant did not have this capacity,

however. Therefore the German armament administration ordered the rebuilding of a sugar factory in Skřivany as an ammunition plant. The conversion commenced early in 1944, and the German party was supplying the necessary equipment itself.

- 1944

- 1945

- On the 24th October 1945 the Company was nationalised. However, it was practically out of service because of a lack of raw materials, coal and especially customer demand.

- 1946

- Production begins to speed up quite rapidly and to increase. The Company was incorporated in the Zbrojovka Brno cartel.

- 1947

- The export of commercial ammunition and detonators reaches a turnover of over CZK 40 million. The Company exports to countries in Europe, South America and Africa.

- 1948

- The Company exports substantial quantities of 7.92 mm ammunition to Israel.

- 1949

- The Company was detached from the Zbrojovka Brno cartel and become a separate enterprise.

- 1952

- The manufacture commenced of new military ammunition of the 7.62 x 45 calibre for the model 52 rifle for the Czechoslovak army.

- 1954

- The production of Fritsch safety cord and electrical primers was transferred to the Company from the Dynamit enterprise in Bratislava.

- 1955

- The Chrástecké závody enterprise, where Bickford safety cord and electric igniters were produced, was incorporated into the Company. During a 10 month period approximately 115 million cartridges of the British 303 model were produced for a

foreign customer.

- 1957

- The production of model 43 military ammunition for the Czechoslovak army (7.62 x 39) was initiated under a USSR licence. The licence was not adopted in its entirety, however, and, unlike the Soviet version, the Czechoslovak producer

manufactured the cases from phosphated steel.

- 1958

- A series of millisecond detonators with 21 delay levels was developed. Their production was never commenced, however, because the responsibility for the manufacture of electric detonators was given to a different company. An explosion

occurred in an underground warehouse containing 1 million No.8. detonators. The damage to buildings outside the company premises was also considerable, however, there was no loss of life or even any injuries. The explosion occurred after

working hours.

- 1959

- The production of safety cord was transferred to the Company from Spolana Neratovice and the Company became the monopoly producer of safety cord in Czechoslovakia. The production of the model 59 ammunition (7.62 x 54 R) for the Czechoslovak

army was initiated under the USSR licence. Even for this product the licence was not fully respected. The cases were produced from phosphated varnished steel. Both types of cartridges under military licence were later also exported.

- 1960

- 14.3 million cartridges of M. 59 (7.62 x 54 R) and 109 million cartridges of M. 43 (7.62 x 39 ) were produced for the Ministry of Defence.

- 1962

- To ensure meeting the planned production volumes, the company introduced the production of high-precision, double-row cylindrical roller bearings and tapered roller bearings. This required a significant investment.

- 1965

- The capacity of the machine works for the production of munitions machines was utilised very irregularly, based on orders from abroad. After World War II 7 turnkey munitions plants were built in foreign countries. Also included in the

production programme therefore was the production of packaging machines.

- 1967

- The worst disaster to take place during the entire existence of the company occurred in the workshop where shotshells were filled. Two hoppers filled with smokeless powder detonated. Eight workers died on the spot and more than 20 were

injured.

- 1980

- Czechoslovakia won an important contract for the aerospace industry from the USSR. Its performance was assigned to the Povážské strojírny Company in the Slovak Republic. This enterprise was a successor to the former plant in Bratislava

belonging to the Viennese company G. Roth and, until 1954 both military and commercial ammunition was made there. Due to the construction of the premises for the performance of the contract for the USSR the ammunition facilities were

liquidated and that production was relocated to Vlašim. Thereby the S & B Company became the monopoly producer of all the ammunition for small arms in Czechoslovakia.

- 1991

- Privatisation of the enterprise using the coupon method. 497,011 shares were issued with a total nominal value of CZK 776,740,000, of which small shareholders received 442,620 shares worth 442.62 million. The manufacture of bearings was

privatised through a public tender.

- 1992

- Transformation of the state-owned company to a joint-stock company - Sellier & Bellot JSC."

- 1999

- Czech Republic joined NATO Aliance.

- 2009

- Sellier & Bellot becomes a member of CBC group.

-

2024

- Sellier & Bellot becomes member of Colt CZ Group SE

Sellier & Bellot Game Preserve

In 1775 Charles Joseph, the Prince of Auersperg, and his wife, Maria Josepha, the Countess of Trautson, decided to create a manorial deer hunting park on the land which is currently the site of Sellier & Bellot.

Fallow deer and roe deer were kept in the park. Pheasants were added later. White and black swans spent the winters in a small wooden building near the pond. Vlasim was a gathering place for the nobility in the autumn.

Aristocratic

guests including Crown Prince Rudolf, the son of Franz Josef I, attended the hunts that were organized there.

Dramatic changes in government took place after the end of the World War 1. The estate came under state control as the result of a newly implemented confiscation law. On June 17th, 1925 the State Land Office, in agreement with

the

Ministry of Education, handed a large part of the estate back to the Auerspergs.

The hunting park was destroyed by a tornado in 1929. As a result, Prince Auersperg decided to sell it along with an adjoining 112 hectares. Sellier & Bellot then purchased the property to build a new factory. On February 22,

1933 the State Land Fund approved the sale of the entire hunting park to Sellier & Bellot.

Mouflon were raised on the property for a short time in the 1980’s. Today, 51 red deer and 28 fallow deer live on 73 hectares of Sellier & Bellot property. These herds are managed to ensure a healthy population. Newly

developed types of ammunition are tested and demonstrated here.

It is also a place where Sellier & Bellot representatives meet customers and business partners.

Significant trophies

deer

- 222.71 p. CIC (2015)

- 217.78 p. CIC (2002)

- 210.98 p. CIC (2008)

- 205.28 p. CIC (2000)

- 203.87 p. CIC (2005)

mouflon

fallow deer

- 204.28 p. CIC (2009)

- 203.97 p. CIC (2006)

- 194.04 p. CIC (2004)

- 194.03 p. CIC (2004)

- 189.63 p. CIC (1999)